Essential Knife Making Tools with Image

Contents

Knives are one of the oldest and most versatile tools in human history. Though their primary purpose is cutting, knives can also be used for a variety of other tasks, such as carving, prying, scraping, and self-defense.

Knives are typically made from a piece of steel that is heated and then cooled to form the blade. The handle is usually made from wood, bone, or another material that can be shaped and attached to the blade.

There are many different types of knives, such as pocket knives, hunting knives, survival knives, and butter knives. Each type of knife is designed for a specific purpose.

Pocket knives are small enough to fit in your pocket and are typically used for everyday tasks, such as opening packages or cutting rope. Hunting knives are larger than pocket knives and are designed for hunting and skinning games. Survival knives are even larger than hunting knives and are designed for use in emergency situations, such as building a shelter or starting a fire. Butter knives are small knives with a blunt edge that is used for spreading butter or jam on bread.

Knives can be dangerous if not used properly. Always be careful when handling a knife and never point the blade at someone else.

20 ESSENTIAL Knife Making Tools for Beginners and Profesional

Knife Making Tools Basic

#1 Safety Gear

The most important thing you need for knife making is a good set of safety gear. This includes gloves, eye protection, and a dust mask. Gloves will protect your hands from sharp blades and hot steel. Eye protection will keep metal shavings out of your eyes. A dust mask will protect your lungs from the fumes generated by grinding and welding.

#2 Computer

You will need a computer to design your knives. You can use any type of computer, but a laptop is best because it is portable and you can take it to your workshop.

CAD Software

You will need CAD (Computer-Aided Design) software to design your knives. There are many different types of CAD software available, but Autodesk Fusion 360 is a good choice for beginners.

3D Printer

A 3D printer is not essential, but it can be helpful. A 3D printer can be used to make prototypes of your knives before you start making them out of steel.

#3 Anvil

An anvil is a heavy piece of steel that is used for shaping metal. It is usually mounted on a stand so that it does not move when you are working on it. Anvils come in a variety of sizes, but a small one should be enough for most knife-making projects.

#4 Hammer

A hammer is used to strike other tools or to shape metal. You will need a variety of hammers for knife making, including a ball-peen hammer, a cross peen hammer, and a chisel hammer.

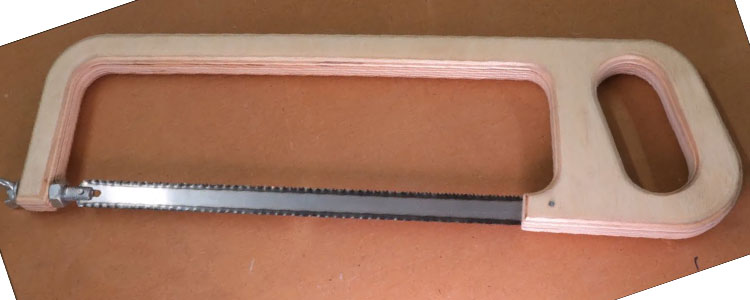

#5 Hacksaw

A hacksaw is a hand saw that is used to cut metal. It has a thin blade with very fine teeth. Hacksaw blades are made from high carbon steel and can be replaced when they get dull.

#6 Calipers

Calipers are used to measure the thickness of metal. You will need a vernier caliper and a digital caliper for knife making.

#7 Clamps

Clamps are used to hold the metal in place while you work on it. You will need a variety of clamps, including C-clamps, F-clamps, and G-clamps.

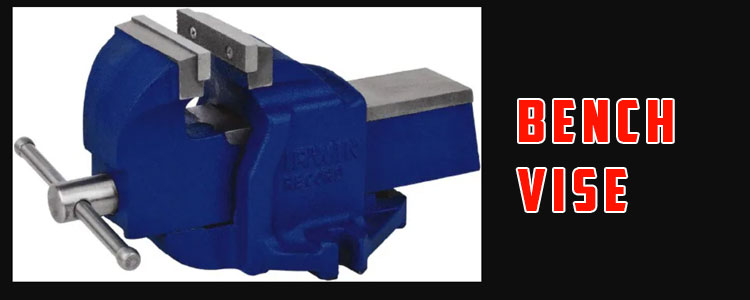

#8 Bench Vise

A bench vise is a clamp that is used to hold the metal in place on your workbench. It has jaws that open and close to grip the metal.

#9 Power Drill

A power drill is used to drill holes in metal. It is also useful for attaching blades to handles with screws.

#10 Files

Files are tools that are used to smooth and shape wood or metal. They come in a variety of shapes and sizes, but round, flat, and half-round files are the most common. Files are made from high carbon steel and are very sharp. Always use gloves when handling files.

#11 Sharpening Stone

A sharpening stone is used to sharpen blades. Sharpening stones are made from different materials, such as diamond, oilstone, and Waterstone.

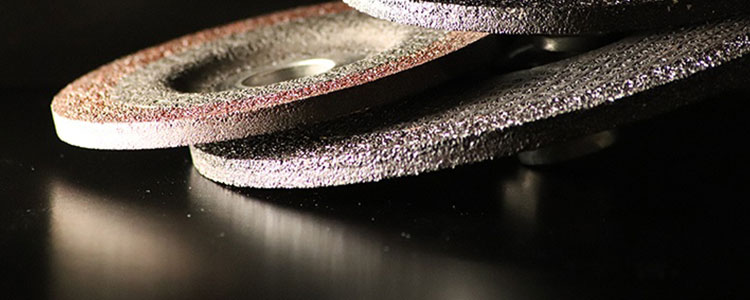

#12 Abrasives

Abrasives are materials that are used to remove metal. Sandpaper is the most common type of abrasive. Abrasives come in a variety of grits, or sizes, from coarse to fine. Coarse grits are used to remove metal quickly, while fine grits are used for finishing.

#13 Belt Grinder

A belt grinder is a powerful tool that is used to grind and polish metals. It consists of two wheels that are covered in abrasive material. The grinding wheel is used to grind the metal while the polishing wheel is used to polish it. Belt grinders come in a variety of sizes, but a 2″ by 72″ belt grinder should be enough for most projects.

#14 Lathe

A lathe is a machine that is used to shape wood or metal. It consists of a bed, a headstock, and a tailstock. The workpiece is rotated on the bed while it is being shaped by the headstock and tailstock. Lathes come in a variety of sizes, but a mini lathe should be enough for most knife-making projects.

#15 Heat-Treating Oven

A heat-treating oven is used to heat treat the steel. Heat treating is a process that changes the properties of steel to make it harder or tougher. Heat-treating ovens come in a variety of sizes, but a small one should be enough for most projects.

#16 Steel

Steel is the material that knives are made from. There are many different types of steel, but carbon steel and stainless steel are the most common. Carbon steel is easy to sharpen but it can rust. Stainless steel is more difficult to sharpen but it does not rust.

These are just some of the most essential tools that you will need to get started. As you become more experienced, you may find that you need other specialized tools. these should be enough to get you started on your knife-making journey.

Knife Making Tools for Profesional (option)

#17 Punching machine

A punching machine is a type of machine that is used to create holes in metal. It consists of a die and a punch. The die is mounted on the machine and the punch is placed in the die. The machine then uses hydraulic pressure to force the punch through the metal.

#18 CNC Machine

A CNC machine is a computer-controlled machine that is used to cut metal. CNC machines are very precise and can produce complex shapes.

#19 Waterjet Cutter

A waterjet cutter is a machine that uses high-pressure water to cut metal. Waterjet cutters are very precise and can cut complex shapes.

#20 Plasma Cutter

A plasma cutter is a machine that uses high-powered plasma to cut metal. Plasma cutters are very precise and can cut complex shapes.

Read more: Custom Chef Knives: How to Choose the Best Knife for Your Needs

FAQs of Knife Making Tools

What is the best metal to make a knife out of?

The best metal to make a knife out of depends on what you will be using the knife for. If you are going to be using the knife for general purposes, then carbon steel or stainless steel would be a good choice. If you are looking for a more specialized knife, then tool steel would be a better choice.

What tools do knife makers use?

Knifemakers use a variety of tools, including lathes, mills, grinders, and heat-treating ovens.

What tools do I need for forging knives?

Forging knives require a few specialized tools, including a forge, an anvil, and a hammer.

What is a good thickness for knife making?

The thickness of the metal you use for knife making depends on what you will be using the knife for. If you are going to be using the knife for general purposes, then a thickness of 3/16″ to 1/4″ would be a good choice. If you are looking for a more specialized knife, then a thinner or thicker metal may be better.

Do old files make good knives?

Old files can make good knives if they are made of high-quality steel. However, most old files are not made of high-quality steel and will not make good knives.

Is rebar good for knife-making?

Rebar is not good for knife-making because it is not made of high-quality steel.

How much do knife makers make?

Knifemakers can make a variety of incomes, depending on their experience and the type of knives they make. Some knifemakers make a few hundred dollars per month, while others make thousands of dollars per month. The average income for a full-time knifemaker is around $50,000 per year.

What is a knife maker called?

A knife maker is called a bladesmith.

What do I need to start forging?

To start forging, you will need a forge, an anvil, and a hammer. You will also need some basic tools, such as tongs and a chisel.

Conclusion

Knifemaking is a complex and rewarding process that requires a variety of tools. In this article, we have only scratched the surface of what is required. But we hope that this has given you a better understanding of the basics of knife making and the tools that are essential to the process. With the right tools and a little practice, you will be able to create beautiful and functional knives that will last a lifetime. Thank you for reading!

2 thoughts on “Top 20 Knife Making Tools [ Attack Images]”